The increasing average temperature of the Earth’s atmosphere is a global environmental problem which continues to grow as a consequence of a constantly rising carbon dioxide (CO2) concentration in the atmosphere. Upper scenarios for CO2 emissions show the rise of CO2 concentration up to 936-1200 ppm by 2100 with global temperature increase by 3 – 5.5°C. Under the lower scenarios atmospheric CO2 levels are forecasted to remain below 450 – 550 ppm with mean global temperature 1.5°C and an increase of global mean sea between 0.26 to 0.77 m. Hence, it is imperative to reduce the emissions of CO2. Developing efficient methods to employ CO2 as an abundant C1 building block to produce chemicals, materials, fuels or carbohydrates is a very attractive approach.

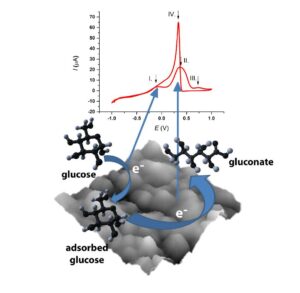

The most common reaction in the conversion of carbon dioxide is catalytic hydrogenation. The main product of the reaction is methanol. As a pure energy option, methanol can be used in internal combustion engines, gas turbines or fuel cells and can also lead to the formation of hydrogen through methanol vapor reformation, which is also pure fuel for energy systems. However, due to the high chemical stability of carbon dioxide and the need to overcome high levels of activation energy, specific catalysts in the carbon dioxide conversion process are needed.

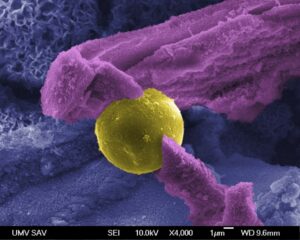

One of the major catalysts used for methanol synthesis is Cu-ZnO-based catalysts, mostly Cu/ZnO/Al2O3, which are currently used in industry. Zinc oxide increases the life of the catalyst in methanol synthesis by removing acidic sites on the alumina phases and prevents the conversion of methanol to dimethyl ether. Although current catalysts provide high selectivity for methanol synthesis, this is still not enough. Promising structures for high methanol production are core-shell nanoparticles that can inhibit unwanted secondary reactions, such as RWGS reaction. Among the possible advantages offered by core-shell nanoparticles, three main ones can be highlighted: (1) the use of the core as a support allowing specific surface (shell) nanoarchitecture in terms of porosity, surface area, etc., resulting in improved catalytic efficiency of such layer (2) the synergy between the shell and the core to achieve higher efficiency/yield/selectivity in catalytic applications; and (3) a combination of core and shell properties towards improved/combined applications. Since these are economically advantageous materials that are still most desirable in industrial catalytic hydrogenation of carbon dioxide, the study of this type of structure is very important and may be applicable in industry in the case of high selectivity to methanol.

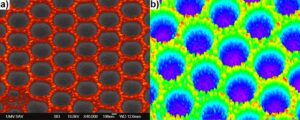

The aim of the research is therefore to prepare ZnO/Cu core-shell nanoparticles with different shell thicknesses, which will subsequently be used as catalysts in the process of hydrogenation of carbon dioxide to methanol. The study is focused on the effect of core-shell nanoparticles on methanol production and the mechanism and results are compared with the literature. The prepared catalysts are intended to increase selectivity towards methanol and reduce the formation of secondary reactions.

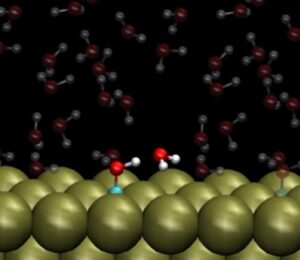

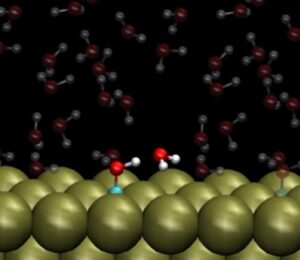

Research consists of three parts, namely (1) the preparation and characterization of particles by a two-step method; (2) chromatographic analysis of catalytic hydrogenation of CO2 to methanol with calculation of kinetic parameters and determination of reaction kinetics by differential and integral methods; (3) computational simulations using density functional theory (DFT) for the theoretical study of the ZnO/CuO interface and a better understanding of the mechanism of CO2 hydrogenation using the studied nanoparticles. DFT calculations determine the most preferred carbon dioxide bond conformations on a given catalyst surface with calculations of the adsorption energy and reaction coordinates of the carbon dioxide conversion on the catalyst surface.

Current references:

Recent Developments in Heterogeneous Catalysts Modelling for CO2 Conversion to Chemicals, N Podrojková, V. Sans Sangorrin, A. Oriňak, R. Oriňaková, ChemCatChem, Vol. 12 (2020). 10.1002/cctc.201901879

Methane Decomposition Over Modified Carbon Fibers as Effective Catalysts for Hydrogen Production, K. Sisáková, A. Oriňak, R. Oriňaková, M. Strečková, J. Patera, A. Welle, Z. Kostecká, V. Girman, (2019). 10.1007/s10562-019-02962-w

Hydrophobicity of highly ordered nanorod polycrystalline nickel and silver surfaces, J. Macko, N. Podrojková, R. Hrdý, A. Oriňak, R. Oriňaková, J. Hubálek, J. Vojtuš, Z. Kostecká, R. M. Smith, Journal of inerals and Materials Characterization and Engineering, Vol. 07, no. 05 (2019) p. 279-293. 10.4236/jmmce.2019.75020

Effect of different crystalline phase of ZnO/Cu nanocatalysts on cellulose pyrolysis conversion to specific chemical compounds, N. Podrojková, A. Oriňak, R. Oriňaková, L. Procházková, V. Čuba, J. Patera, R. M. Smith, Cellulose, Vol. 25, no. 10 (2018) p. 5623–5642. 10.1007/s10570-018-1997-7

Catalytic activity of mono and bimetallic Zn/Cu/MWCNTs catalysts for the thermocatalyzed conversion of methane to hydrogen, B. Erdelyi, A. Oriňak, R. Oriňaková, J. Lorinčík, M. Jerigová, D. Velič, M. Mičušík, M. Omastová, R. M. Smith, V. Girman, Applied Surface Science, Vol. 396 (2017) p. 574-581. 10.1016/j.apsusc.2016.10.199

Methane Decomposition over Carbon Microfibers with Ni, Co, Cu Nanoparticles Modified Catalysts to Produce Hydrogen, K. Sisáková, A. Oriňak, Hydrogen Days 2019: Through collaboration to the deployment of H2 technologies. – Prague: Czech Hydrogen Technology Platform. 2019

· Winner of the Best Contribution Award for her poster presentation

Carbon microfibers as a support for catalyst for thermal decomposition of methane to produce hydrogen. K. Sisáková, A. Oriňak, R. Oriňaková. International Conference on Innovative Applied Energy IAPE. – Oxford: University of Oxford, 2019

ZnO/Cu core-shell nanoparticles for CO2 conversion to methanol. N. Podrojková, A. Oriňak, R. Oriňaková. International Conference on Innovative Applied Energy IAPE. – Oxford: University of Oxford, 2019

Synthesis of Pd-NiFe2O4/SiO2 Catalyst for thermal decomposition of methane to hydrogen. K. Sisáková, A. Oriňak, R. Oriňaková. Czech and Slovak Chemistry Congress 2019, High Tatras: Czech and Slovak Chemical Society, 2019

ZnO/Cu nanocatalysts for thermochemical conversion of CO2 to chemicals. N. Podrojková, A. Oriňak, R. Oriňaková. Czech and Slovak Chemistry Congress 2019, High Tatras: Czech and Slovak Chemical Society, 2019

Synthesis of Pd-NiFe2O4/SiO2 Catalyst for thermal decomposition of methane to hydrogen. K. Sisáková, A. Oriňak, R. Oriňaková. New trends in chemistry : Trends in chemistry, research and education at Faculty of Science of P.J. Šafárik University in Košice. – Košice: Pavol Jozef Šafárik University in Košice, 2019

Core-shell Nanoparticles for CO2 Hydrogenation to Methanol. N. Podrojková, A. Oriňak, R. Oriňaková, New trends in chemistry : Trends in chemistry, research and education at Faculty of Science of P.J. Šafárik University in Košice. – Košice: Pavol Jozef Šafárik University in Košice, 2019

Decomposition of Methane Over Carbon Microfibers Modified by Ni, Co, Cu Catalysts to Produce Hydrogen, K. Sisáková, A. Oriňak, New trends in chemistry : Trends in chemistry, research and education at Faculty of Science of P.J. Šafárik University in Košice. – Košice: Pavol Jozef Šafárik University in Košice, 2018

Catalytic Pyrolysis Conversion of Cellulose to Specific Chemical Compounds, N. Podrojková, A. Oriňak, R. Oriňaková, L. Procházková, V. Čuba, J. Patera, R. M. Smith, New trends in chemistry : Trends in chemistry, research and education at Faculty of Science of P.J. Šafárik University in Košice. – Košice: Pavol Jozef Šafárik University in Košice, 2018